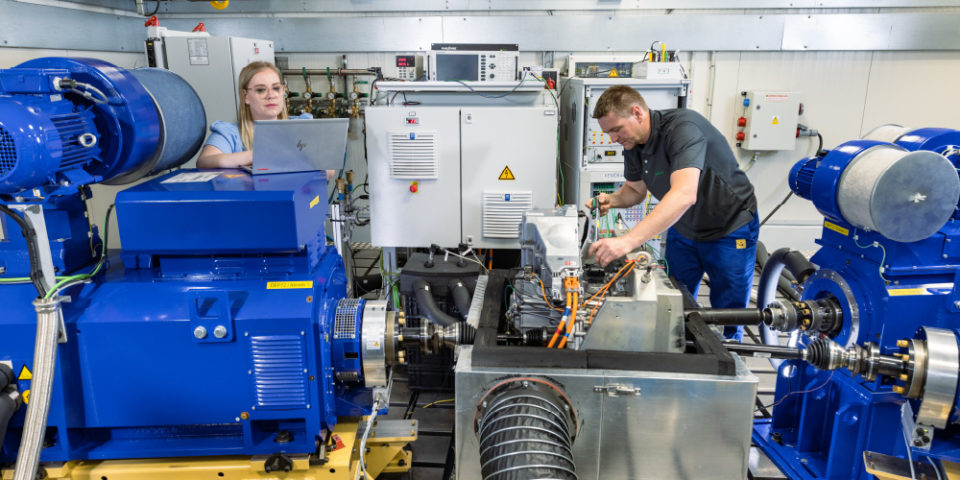

We specialize in testing entire systems as well as components of our own products within the Schaeffler Group. These tests are functional, life cycle tests as well as simulations of external environmental influences concentrated in individual test sequences, which are technically and technologically demanding and can perfectly test our innovations for hybrid and pure electric cars. In most cases, we are testing innovations and prototypes that will go into series production in a few years’ time. Some of them will also be part of autonomous vehicles.

Sequential tests are a block of up to a hundred different tests, including mechanical, electrical and environmental tests. The test facility is equipped with state-of-the-art technology, measurement systems and stations that meet the most stringent safety requirements.

Thanks to special climate chambers, we can create a simulation of the real environment for the test sample as if it were in a real vehicle, including extreme situations. We can control the ambient temperature, but also the temperature of the oil or coolant. We also use universal climate chambers in our tests, as well as salt chambers that are equipped with inputs to control the sample via additional measuring technology, or shock chambers to test samples during temperature shocks. In the shock chamber we can induce a thermal shock from +220 °C to -80 °C in 20 seconds.